With your shaper utilizing the CNC machine, you CAN have that magic board again, and for the rest of your surfing life. If you happen to break that magic whip you’ve had for years, you may want the exact same board again. Either way, the creative process and “soul” of the board is still there, and they can now duplicate models for the team riders and customers. This comes as a benefit for both the shapers and the customers riding their boards.

#Used aku shaper for sale how to#

Other shapers (still with a deep knowledge and experience with shaping by hand) learn how to design boards using the CAD program, have it cut and finish it by hand. After this they can have the board scanned, or the can manually enter all the dimensions needed into a CAD file. So, for many shapers, the creative aspect of shaping the new model is still done by hand. They may spend their time hand shaping and creating a new model until it is dialed in to where they want it. Most of them (not all, but most of them) who are coveted as master hand shapers, may still use the machine for their production schedule. You will be surprised by the number of shapers you think are “hands only” shapers. It saves shapers a little bit of time, and helps to ensure that they can get better results when duplicating certain models. This is the stage that a machine cut will get you to, as opposed to taking an electric planer and doing it by hand. Now, most of the detailed shaping comes after a board has been roughed out.

That’s where the majority of skill comes into play, and that’s not even counting the glassing process, which is a whole other level in itself. But you’re not done there, you still have to finish shape it to perfection.

#Used aku shaper for sale download#

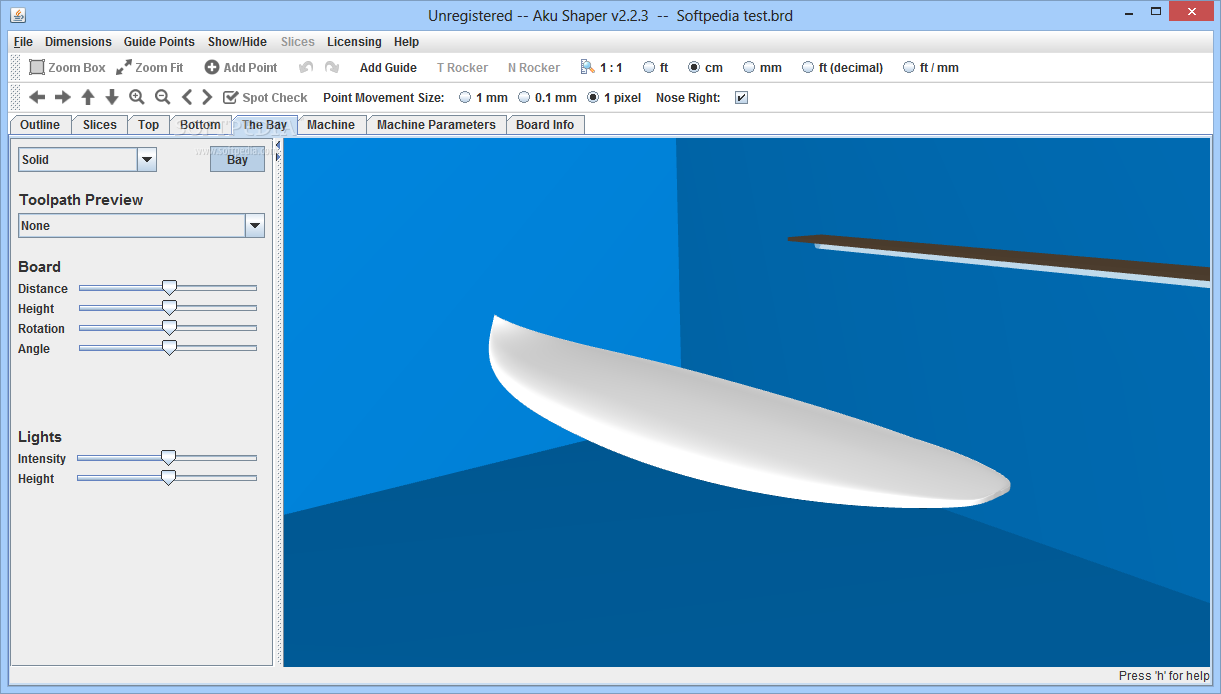

If you have never played around with a CAD file, go download a free program like Shape3D or AKU Shaper, design a board, and see how it really turns out when it comes out of the machine. You have to know these principles and theories, and you have to be able to hand shape at a high level to get even a decent design out of a CAD file and a machine cut. But in reality, you still have to have an understanding of how and why boards and design principles work. Sure, anyone CAN do it, just like anyone CAN get a blank and some tools and hack their own board out. The old phrase “work smarter, not harder” holds weight, no matter what your job entails. In today’s world, the CNC shaping machine is that fast and efficient tool, used by the majority of shapers worldwide. In any industry, people have to adapt and explore new tools and ideas that can make their job easier and more efficient. Originally, they were designed as a tool to take the place of block planes, mostly used for truing up and hanging doors, or other flat areas like floors, table tops and decks.Īs production demands began to grow for shapers, they had to look for more efficient tools to help get the job done faster and more accurately. The electric hand planer was not invented for surfboard shaping. There must have been guys sitting in their garage bickering about how the “soul” of a surfboard gets lost when people started using electric tools to do the work where elbow grease, sweat and a few block planes were your shaping tool quiver.

I am sure the debate over the purity of surfboard shaping has been going on continuously probably since the electric hand planer was introduced.

0 kommentar(er)

0 kommentar(er)